Do You Know Your Biogas Feedstock?

UIT´s slogan “Test before invest” is not followed by research centers, only. Providers of large-scale biogas plants are showing increasing interest in testing the fully equipped biogas pilot plants in the planning phase. It is precisely the existing trends that dictate high prices for biogas feedstocks which more and more often leads to considerable difficulties in operating biogas plants economically. The BTPs also give customers the option of adapting existing large-scale plants to these new challenges on a small scale to the suitability of raw materials, ensuring continuous, stable, and sustainable operation in the run-up to the adaption of the large-scale plant. This saves time and considerably reduces investment costs.

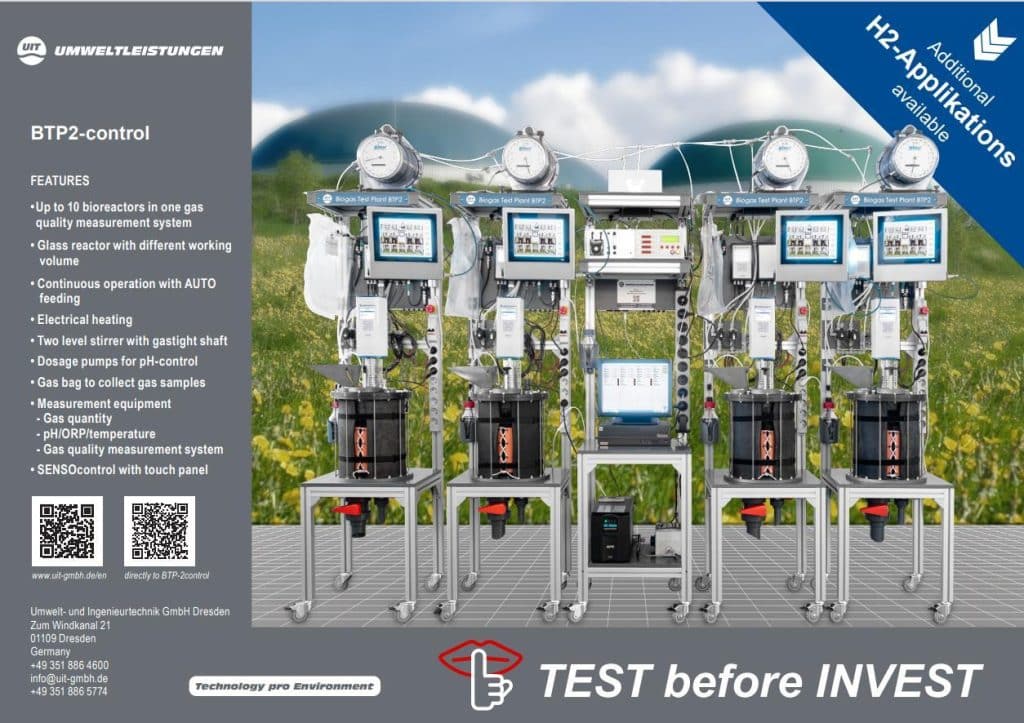

A new standard biogas test plant (BTP), BTP2-control, complete with an internal gas quality measurement system, has been launched by Umweltund Ingenieurtechnik (UIT) Dresden. UIT has been providing biogas test plants for decades. The latest plant, BTP2 control, has been enhanced and adjusted to meet the latest customer needs.

The system is standardized in terms of fermenter sizes, agitator, heating, feeding, discharge, and measurement technologies. Figure 1 shows a set-up with 4 fermenters in parallel. Up to 10

fermenters can be integrated into one BTP2-control plant and equipped with one gas quality analyzer. With this new test plant, continuous biogas potential analyses of the feedstock can be achieved and optimized.

Sustainable biogas production must address multiple factors, including the continuous evaluation of the feedstock and its compatibility with the biomass in the reactor to avoid process interruption; feedstock types, critical processing parameters, and substrate quality.

You must understand the biomethane potential of your feedstock, and the microorganism lifecycle and its activity in the fermentation process.

Qualify the biogas process

It is important to address the challenges related to the economic sustainability of biogas production and utilization. The energetic value and the availability of suitable raw materials as a source for biogas production ensuring continuous, stable, and sustainable operation is a challenge that involves many individual aspects of the entire process chain. Biogas production differs from country to country in terms of volume and feedstock sourcing. The yield and composition of biogas vary depending on the morphology of feedstock and calls for research and development (R&D). UIT offers biogas tests plants as single-stage BTP2; complex multi-fermenter biogas tests plants (BTP2- control – see Figure 1), and biogas plants equipped with multiple larger volume fermenters.

The BTP – a technical solution

Existing trends dictate high prices for biogas feedstocks and can lead to considerable difficulties in operating biogas plants economically. This has generated a lot of practical interest in controlling the composition of feedstock or using alternative substrates. The BTP as a technical solution was developed in a modular design, constructed according to ergonomic aspects for practical use. It can be easily adapted according to individual requirements. The customized configurations range from single reactors to multiple reactors as R&D laboratory instrumentation to containerized solutions for use in large-scale biogas plants. BTP2 is the basic system for substrate testing and gas yield investigations. Furthermore, this system is ideally suited for product development (enzymes, nutrients) or process optimization. This system is characterized by its extensive basic automation system, SENSO control, with a panel for process control, data acquisition, and storage as well as data interpretation in graphs or tables. The system can be expanded with pumps for feeding, special control sensors and other elements. The ‘pumpability’ of the feedstock is a challenge for the BTP. A special large-volume syringe piston pump was developed to feed the plant.

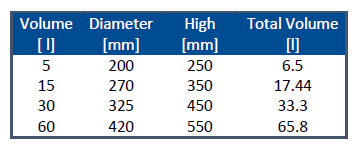

Bioreactor sizes

Standard reactor sizes range from 5 to 60 liters. The 15-litre bioreactor has proven to be an excellent size to achieve transferable research results for many applications. Figure 2 shows the reactor dimensions. BTPs are equipped with gastight, heated, stirred, or isolated bioreactors, designed for fermentation processes. The temperature of the bioreactor can be set up to 60°C – higher temperatures require a different construction material. Feedstock feeding port, discharge and sampling valves are arranged directly accessible. To ensure adequate mixing and degassing of feedstock material, the reactor has a two-stage agitator with an adjustable speed of between 5 and 240 rpm.

For more information: Visit: uit-gmbh.de or email: vertrieb@uit-gmbh.de

Comments